Metal sheets are materials used in almost every sector of the economy. Some industries that use sheet metals include; electronics, medical industry, automotive industry, robotics sector, energy sector, and aerospace sector. Sheet metal is now an essential commodity for the smooth running of the economy. The development of technologies like sheet metal prototyping has allowed for the creation of high-quality sheet metal. If you require sheet metal fabrication, you should look for the best rapid prototyping company and outsource your services. This post aims at informing you of reasons to acquire sheet metal prototyping services.

Meaning of sheet metal fabrication

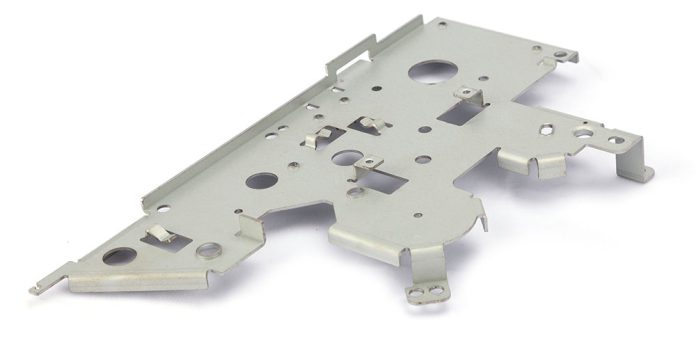

Sheet metal fabrication is a combination of several manufacturing procedures that allows for turning the metal sheet stocks into parts that can function well. The sheet metal thickness in centimeters is usually between 0.015 and 0.635.

In addition, the various procedures included in sheet metal fabrication processes include; punching, cutting, and bending. The various techniques can either be used separately or together. The sheet metal fabrication process develops end-use components or prototypes that are fully functional.

What are the reasons for acquiring sheet metal prototyping services?

1. Durability

Sheet metal prototyping processes help in the production of very durable end-use parts or functional prototypes. Industries such as the automotive industry require durable sheet metals. The prototyped sheet metal should be able to provide an automotive with services for an extended period.

2. Metal selection

Different industries use different metal parts for various uses. The best advantage of acquiring sheet metal prototyping services is that sheet metal fabrication allows you to choose whatever metal you need from the wide array of metals that are in existence. The metals can include; copper, aluminum, steel, zinc, and stainless steel.

3. Thickness choice

The sheet metal thickness used in the medical device is not the same as the one used in an automotive part. Therefore, one of the best advantages of acquiring sheet metal prototyping services is that it allows you to pick whatever size you need for your prototype.

4. Very affordable

The cost of production is very significant for every industry. If you are aiming for mass production of your products, then sheet fabrication offers the best advantage. The cost of sheet metal fabrication is very cheap; the more outputs you need, the more affordable the services will be.

5. The finishing choice

One of the best merits of acquiring sheet metal prototyping services is that you can choose whatever finishing option you need. The Finishing choices available include; anodizing, powder coating, custom finishes, and bead blasting. The finishing options ensure that you get your prototype however you desire it to look and feel.

6. Fast prototyping services

With prototyping, you do not have to wait for long periods before delivering your end products. Some of the best prototype manufacturing companies in existence take only between five to ten days for your prototype to be ready. Also, the presence of modern technologies ensures that speed and quality go hand in hand.

Conclusion

Sheet metals can be applied in several industries to create several appliances such as doors, brackets, body panels, office equipment, kitchen equipment, enclosures, and several others. The list of benefits that comes with acquiring sheet metal prototyping services is endless. Every sector in the economy uses sheet metals. Therefore, the above are some of the benefits that come with sheet metal prototyping processes.