A gold melting machine can be used to melt gold ingots, scrap and nuggets into liquid metal. Gold melting machines are available in different types, sizes and capacities. Here is a discussion on the different types of gold melting machines available in the market.

The Different Types of Gold Melting Machines:

There are many types of gold melting machines available based on their size, capacity and application. Some of the most popular types of gold melting machines are discussed below:

Casting Machines:

Casting machines are the most common type of gold melting machines used by people who want to melt their own jewellery at home or even professionals who want to melt scrap gold into ingots for sale. These machines are portable and can be used anywhere. They come with a small crucible which can be placed inside a refractory brick box that acts as a furnace for heating the molten metal. The molten metal is poured out through a tap hole located at the bottom of the brick box after heating it up to its maximum temperature (1800-2000 degrees Celsius).

Melting Furnaces

Melting furnaces are used for high volume production of jewellery and other small goods, as well as for refining precious metals and alloys. These devices are designed to melt large amounts of material at once and produce very high temperatures. They can be fuelled by electricity or gas; some also use oil or coal for added versatility.

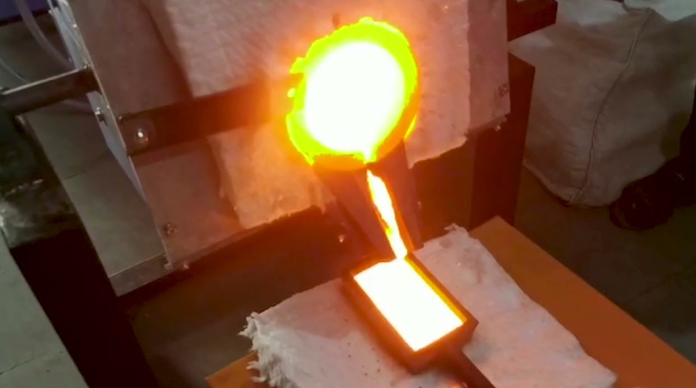

Induction Melting Machines

Induction melting machines are the most common type of gold melting machine. An induction heating unit is a large, heavy piece of machinery that heats up the metal with electromagnetic waves. The electromagnetic waves create heat inside the furnace, which melts down the gold and other metals like silver, platinum and palladium.

Electrolytic Melting Machine

Electrolytic melting uses electricity to separate the gold from other materials in raw ore. The ore is crushed and put into a solution that dissolves the metal. Next, an electrical current is applied that attracts the metal, causing it to form into small droplets that float on top of the solution. The droplets are collected and purified by heating them in another container until they melt completely into liquid form. Electrolytic melting machines can produce up to 100 ounces of gold per day and are most commonly used by large mining companies or refineries.

Arc Melting Machine

The Arc Melting Machine is an electric furnace that melts gold and other precious metals. This type of machine is used by jewelers because it produces very little smoke and uses less electricity than other melting devices. The arc machine uses an electrical current to heat up the crucible, which must be made out of platinum or another non-reactive metal.

Crucible Furnace:

A Crucible Furnace is a type of melting unit that uses a crucible to melt metal. Crucible furnaces are usually used in metallurgy applications where large amounts of molten material need to be melted at once (such as gold, silver and other precious metals). A typical crucible furnace consists of a metal container filled with sand, which acts as a heat sink, and a gas-fired burner underneath it.

Conclusion

The way you melt or refine your gold is something that you should take seriously. It is important for you to spend some time and consider which type of machine would be best for your needs. So, if you like gold, then this blog is well worth checking out.

Different people have different needs, and what works best for melting your gold may not necessarily work well for someone else. Each machine has its own advantages, its own disadvantages, and is suited to different applications. The important thing is to examine the facts, compare them with your own findings, and decide which system will be best for you.